| EXERCISE - CHEMICAL INDUSTRY: NETCAR |

| 1.- OBJECTIVE |

| The purpose

of the exercise is to study the alternatives whereby a company that specialises

in the cleaning of chemical tankers (tanker truck wash) can: - Reduce its water consumption. - Comply with the waste water dumping regulations. - Minimise investment in the on-site waste water treatment plant. The company in question is the NETCAR Company in the chemical industry. The particular issues here are: |

|||

| 1. What

actions can be carried out to reduce the total water consumption and waste

water that is generated by the company? 2. What will water consumption and waste water generation (volumes) be after the proposed alternatives have been put into practice? |

|||

| 2.- AVAILABLE DATA |

| The

basic data for this exercise include: - A general description of the Company. - Description of the plant facilities. - Water consumption. - Characteristics of the waste water produced. - Number and description of waste flows generated. The causes of waste flow generation. Current management practice. |

||

| 2.1.- GENERAL DESCRIPTION OF THE COMPANY |

|

The NETCAR company uses

a cleaning system that has a very high water consumption and produces

a large quantity of waste water (with a high overall pollutant load). |

||

| 2.2.- DESCRIPTION OF THE PLANT FACILITIES |

|

Tanker truck inside

wash units |

||

|

Tanker truck outside

body wash unit |

||

|

Waste water treatment

plant |

||

| 2.3.- WATER COMSUMPTION |

| Water consumption

is highly irregular. Consumption only occurs during working hours in the

truck washes. The tanker truck inside wash units consume large quantities of water when water is being injected under high pressure. Estimated flow in this facility is (average daily volume): - Tanker truck inside washing: 100m³ / day - Tanker truck outside body wash: 20m³ / day |

||

| 2.4.- CHARACTERISTICS OF THE WASTE WATER PRODUCED |

|

The pollutant load of the

waste water produced in tanker truck inside washing is highly variable,

depending on the products that have been transported in the tanks and

also how much they have been emptied (i.e. the amount of product that

remains inside the tanker when it reaches the inside wash unit). |

||

| 3.- APPROACH |

| The issue here

is to find possible alternative ways to recycle and segregate the types

of waste water. A circuit needs to be designed for the water that takes

account of the rate of pollutant load from the activities described above

[tank cleaning and vehicle cleaning]. Up to 50% of the outside body wash water can be recycled with the appropriate modifications (redesign). With the correct management of water, only 10% of the water from the outside body wash facility should have to go to the treatment plant. From the description of the processes and the data provided: |

||

| - Identify actions

that can be carried out to reduce the company's total water consumption

and the amount of waste water that is generated. - Calculate the water consumption and the amount of waste water generated after the proposed alternatives have been applied. |

||

| 4.- ANSWER TO THE EXERCISE |

| 1.

Minimisation actions: A critical analysis of the Company's water requirements |

|||

| - The preliminary

hose-down inside the tanks requires clarified water although it is not necessary

to consume mains water, as is done at the present time. - Likewise, the prewash water used in the outside body wash unit does not need to be pure mains water. Clarified water with no dissolved pollutant load is sufficient. - Waste water produced in the outside body wash facility is all treated in the treatment plant although neither the physiochemical treatment nor the biological treatment are necessary as long as this water is not mixed together with water from inside washing (which is highly polluted). |

|||

| Proposal

to modify the cleaning system and to use water with different qualities. |

|||

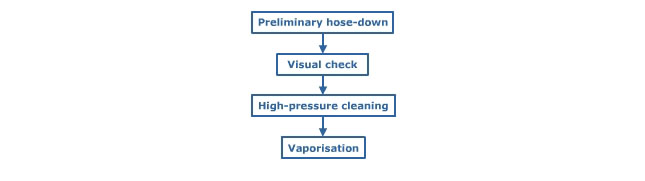

| - Inside

wash Certain changes of operation are proposed, together with the use of different quality water: |

|||

| •

Segregate the wash water containing residual product from the tanker when

it arrives at the wash facility and store in containers or drums. This is

to be managed as waste through an authorised waste manager. This will lead

to a big decrease in the pollutant load of the water sent to the treatment

plant. • The preliminary low pressure hose-down could be done using output water from the treatment plant. This water is clarified and although it contains a moderate level of dissolved contamination, it could be used for the first rough wash-down of the tank. A 20% saving of water consumption can be achieved with this action in the inside wash facility. • For very high pressure cleaning, the proposal is made to continue using mains water, given that the equipment is sensitive. |

|||

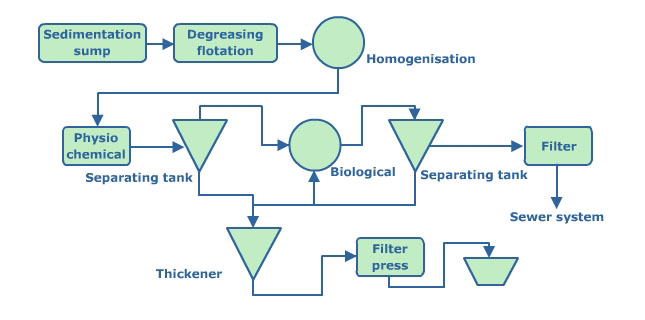

| - Outside

wash Waste water segregation and the reuse of water are the proposals made here: |

|||

| • The waste

water produced in this facility practically only contains suspended matter

although there is very little dissolved pollution. It does not make sense

to mix this with highly contaminated water from inside washes or water that

needs to be treated in the physiochemical system or biological treatment

process. • Given that these waste waters enter a separating tank first and are then pumped to the treatment plant, the proposal is made to replumb the system and to pump them directly to the sand and anthracite filter which is currently under-used. Filtered water is recycled and can be entirely used for outside washing of the tankers. To prevent the concentration of dissolved grime, part (10%) of this water is drained off and sent to the treatment plant. • Rinsing is done with mains water while decalcified water is used for the final rinse. • A 50% saving of water consumption can be achieved with these actions in the outside wash facility. |

|||

| 2.

Calculating the water consumption and the quantity of waste water generation

after the proposed alternatives are put into practice. Quantifying the savings Water conservation in the inside wash facility: 20% * 100m³/h = 20m³/h Water conservation in the outside wash facility: 50% * 20m³/h = 10m³/h TOTAL WATER CONSERVATION: 30m³/h (Initial water consumption following minimisation and with no consideration of recycling: 90m³/h) Waste water treated in the treatment plant: From inside washes (1): 100 - 20 = 80m³/h From outside washes (2): 10% * 10 = 1m³/h TOTAL WATER TREATED IN THE TREATMENT PLANT: 81m³/h Calculations: Final water consumption: 80m³/h + 1m³/h* = 81m³/h (*9 m³/h remaining are recycled) (1) This waste water will have a lower pollutant load, which at the outset is non-quantifiable due to segregation of the tanker rinses. (2) Only the part drained off of the water recycling circuit, which is estimated at being 10% of consumption, would go to the treatment plant 3. Conclusions: Through these action, 33% of the capacity of the treatment plant would be opened up, or in other words, tanker cleaning activity could be increased by 33% without the need for any investment in enlarging the treatment plant, with a water consumption that is lower than initially. Furthermore, these actions guarantee that, despite an increase in activity, the treatment plant will continue to comply with the limits established for discharged pollutant load. |

|||