| EXERCISE - LEATHER INDUSTRY: SABXAI |

| 1.- OBJECTIVE |

| The objective

is to determine what options are available for making improvements to the

pickling process to minimise the waste flows and reduce processing costs

at the same time. The fundamental issues here are: |

|||

| 1) What

ways (opportunities) can the pickling process be improved? 2) What economic saving can be made from alternatives to make improvements? |

|||

| A presentation is given of the SABXAI Company, which specialises in leather tanning, with particular details of the pickling process. | |||

| 2.- BACKGROUND |

| The

following data are basic to this particular case: - Presentation of the SABXAI Company. - Description of the pickling process. - Materials and products used. - Equipment used. - Number and description of waste flows generated. Causes of generation and current management. - Data for calculating the period of return on investment. |

||

| 2.1.- INTRODUCTION TO THE COMPANY |

|

This is a leather tanning

factory that specialises in processing hides for shoe leather using sheepskin

originating basically from the Mediterranean area. The main raw material

used is raw sheepskin hide. |

||

| CONSUMPTION | ||

| Raw sheepskin hides |

346,569

hides/year

|

|

| Water |

103,634

m³/year

|

|

| Production process: 82% |

84,977

m³/year

|

|

| Domestic and sanitary use: 18% |

18,657

m³/year

|

|

| Energy | Electricity |

3,000,000

kW/year

|

| Fuel |

630

t/year

|

|

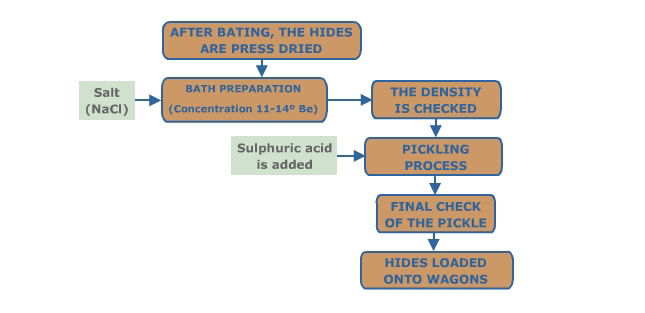

| 2.2.- DESCRIPTION OF THE PICKLING PROCESS |

|

Following the bating operation

(also known as drenching), pickling, which has various different purposes,

is carried out in the same paddle vat. These include: |

||

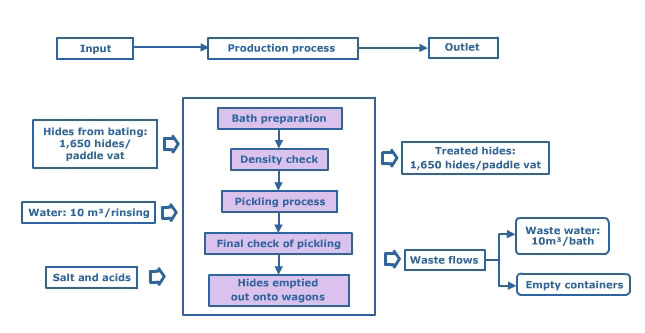

| 2.3.- MATERIALS AND PRODUCTS USED |

| The hideS: The hides come from the bating process: in the pickling process, 1,650 raw hides can be processed in each of the two facilities (paddle vats). Water: The consumption for each rinse is 10m³ and the cost of the water, including the cost of treatment, is EUR 1.36 /m³. Salt and acids: Sodium chloride in liquid form is used. This is delivered in tubs and stored in an on-site tank. Acid comes in 100 kg plastic drums and is stored in the section where processing takes place. |

||

|

Salt

The purpose of adding salt is to prevent the acid swelling produced by osmotic pressure. A density of around 5-6º Be is sufficient to prevent swelling although a lower density can also be effective. For reassurance purposes, however, preservation pickles carried out by the Company have a working salinity concentration of 11-14º Be. Salt can be added in two ways: - Bags: the inconvenience is that this is not very practical because there are various operations that require salt, which involves physical effort by the worker who has to carry the bags. - A 20-21ºBe concentrated brine solution: The tubs are delivered and emptied into a tank; the salt is then pumped to the different areas of the factory. The SABXAI Company uses the second method, with the savings and advantages that this involves. Sulphuric acid As more acid is used in preservation pickling to prevent a change in the pH, more salt is added. If the hide is highly saturated with salt, penetration of the chrome salts will be more difficult in the tanning stage and they will not fix as well because the fibre will be more dehydrated and access to reagent groups will be more difficult. Formic acid and sulphuric acid are mostly used although monovalent acids (formic, acetic) penetrate very rapidly and give offcuts that are more uniform and a finer grain. The SABXAI Company uses sulphuric acid as a reagent because it is more effective in stabilising the hide (compared to organic acids) in that it forms transversal electrostatic links in the following way: --- NH3 --- SO4 --- NH3 --- The longer that pickled hides can be left to soak, the more they will be etched by the action of the acid hydrolysis. This is further enhanced if organic lyotrophic acids are used in the pickle and sulphuric acid used for greater stabilisation. |

||

| 2.4.- EQUIPMENT USED |

|

The same equipment is used for both pickling and bating and it consists of a polyester tipper paddle vat. The hide/water ratio is 1/5, i.e. for one kilo of hide, 5 litres of water are required. Consumption per process is 10m³ and 180 processes are carried out per year. |

||

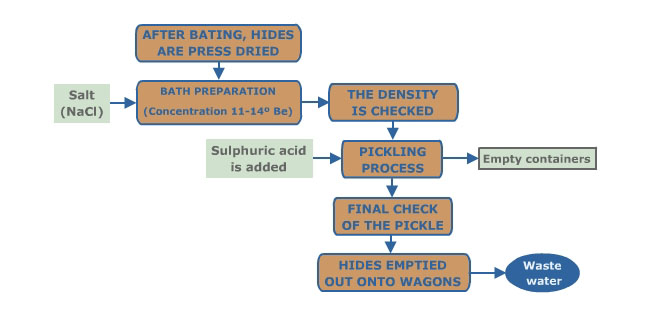

| 2.5.- Number and description of waste flows generated - The causes |

| of waste flow generation and current management practice |

|

The waste flows generated

in this process are as follows: |

||

| 3.- APPROACH |

| Available data

include: |

||

| - Development

of the pickling process - Materials used and consumption - Identification of the waste flows and their characteristics |

||

|

These data provide the

necessary information to determine which improvement is most appropriate

as a proposal for the pickling process. |

||

The minimisation alternatives need to reduce the waste flows being generated, i.e. reduce the water consumption, reduce the pollutant load of the waste and reduce the amount of products used. Aside from the option to be proposed, evaluation is also necessary of the technical feasibility and economic viability, together with the investment payback period. |

||

| 4.- ANSWER TO THE EXERCISE |

| Description

of the alternative The residual baths already contain the products that need to be added when starting the pickling operation so they can be reused here in this operation. The improved alternative proposed is to RECYCLE THE PICKLING BATH (up to 70% can be recycled). With this recycling, two objectives can be achieved in just one operation: - The consumption of water, sodium chloride and sulphuric acid is reduced. - The dumping of a high concentration of salts and acids is prevented. |

||

| 2.6.- ECONOMIC DATA |

|

Investment |

||